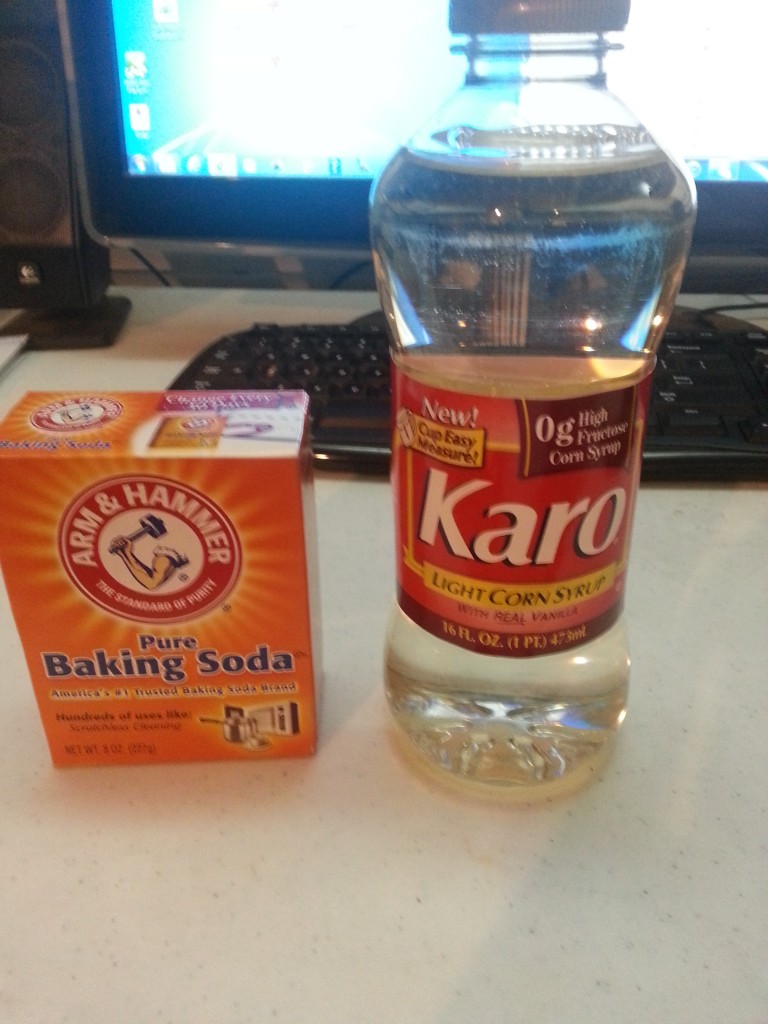

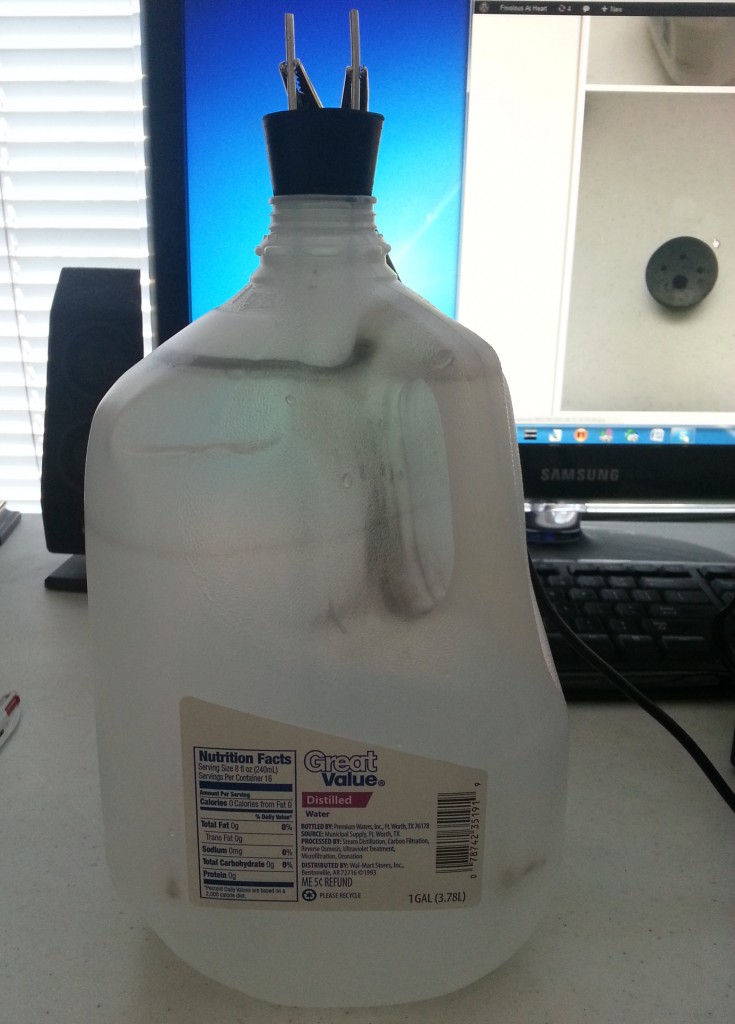

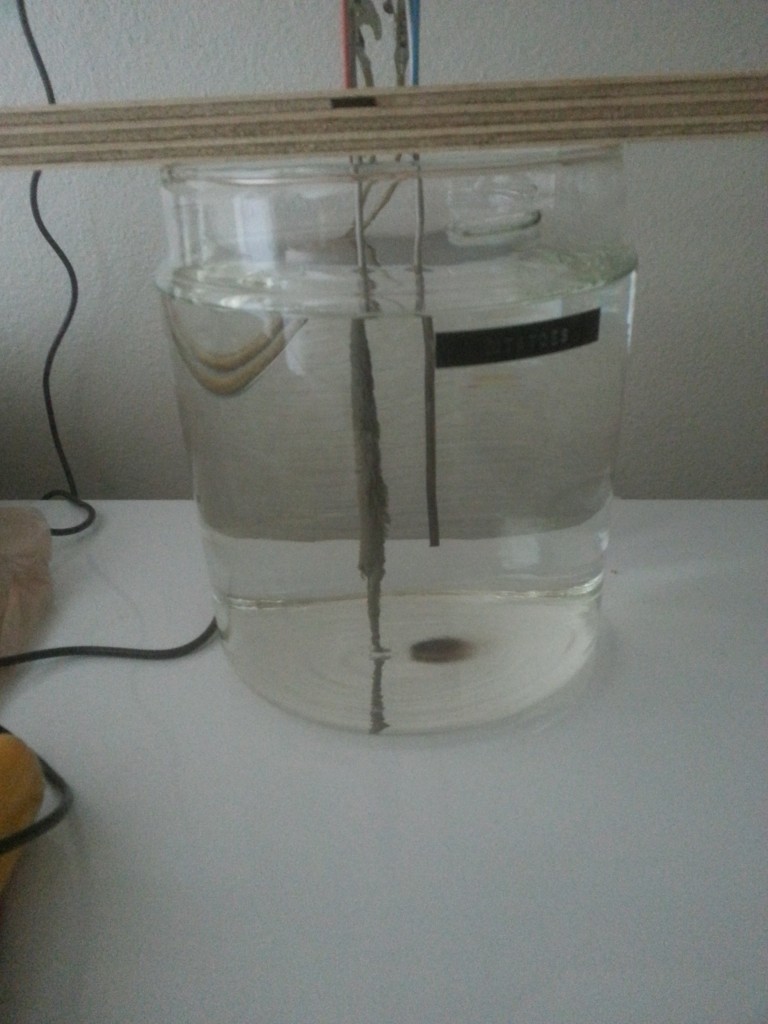

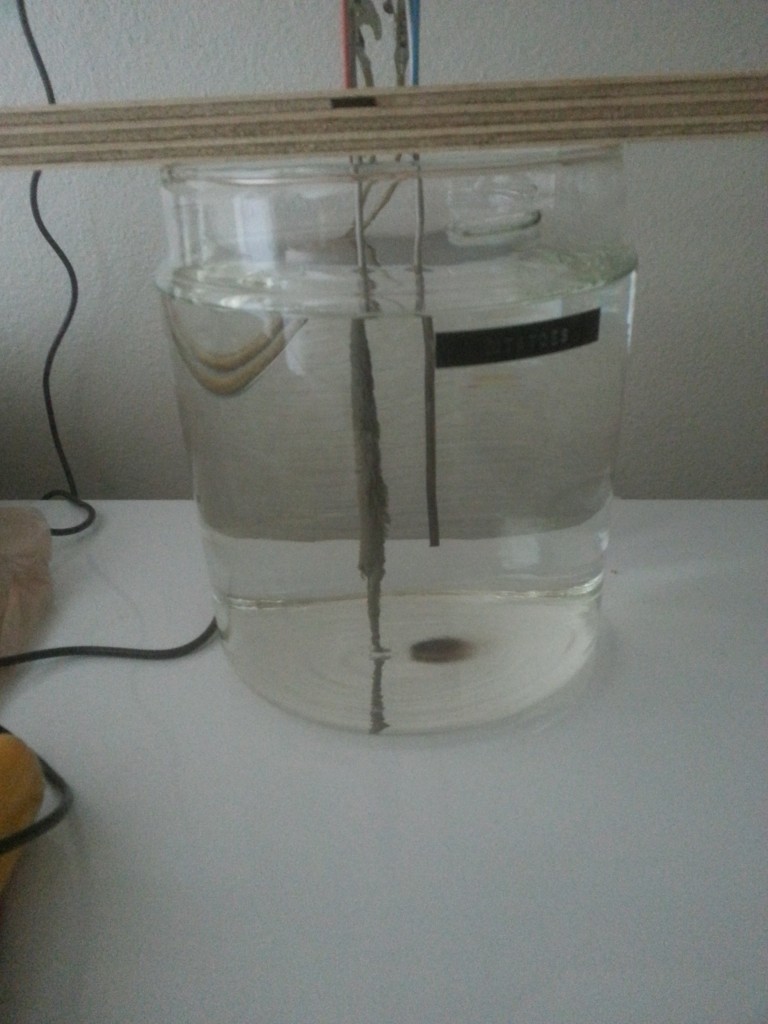

I started out with a gallon of distilled water. This is just a test. I’ll make it’s more presentable and user friendly with the completed product. 12 volts @ 1.8a. I set it for 30 minutes. Lets see with my PPM tester how it comes out!!! Nothing!

Colloidal silver that is clear or with high PPM is most likely ionic and not TRUE colloidal silver as stated by Silverlungs. These solutions are generally bought from Amazon and the likes. Ionic CS conducts electricity and you don’t want that. True CS are for chloride-rich environments such as our stomach and blood whereas ionic CS isn’t.

EDIT: 09-15-12

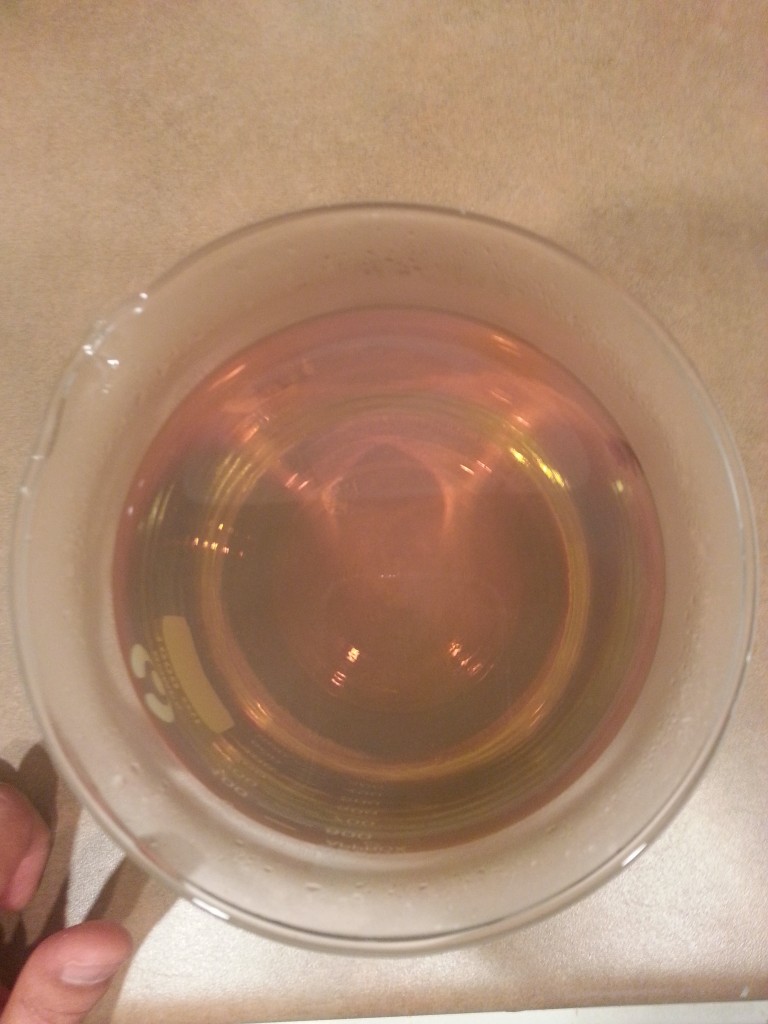

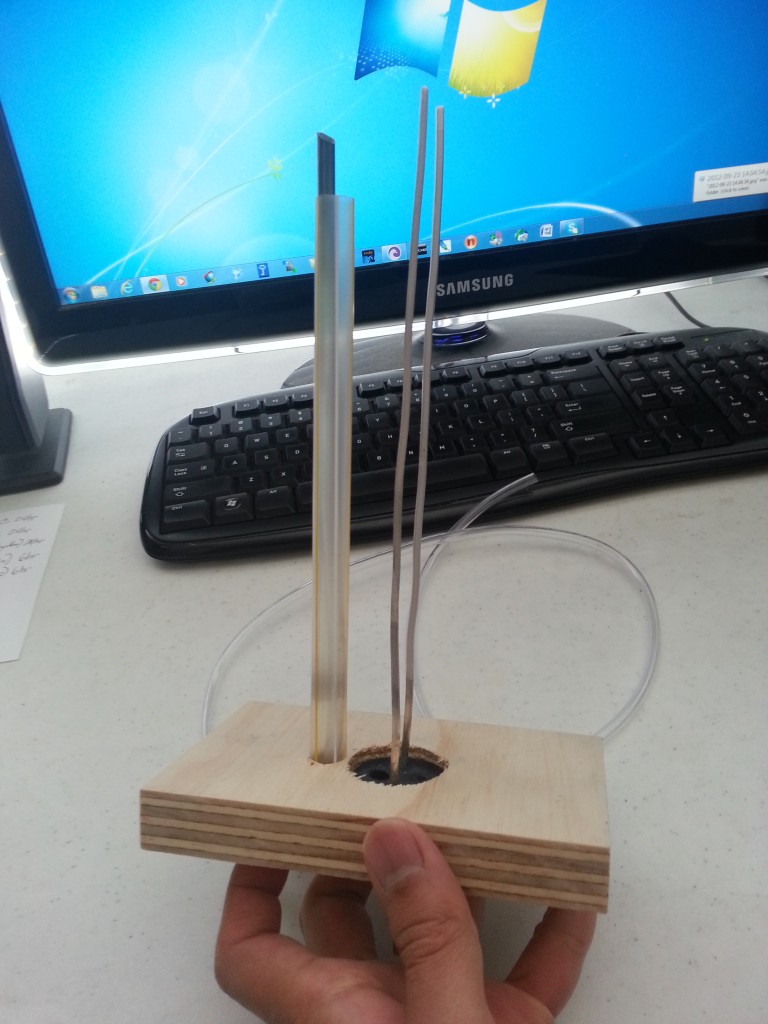

My first batch came out yellow. Still good to use internally or externally but I will use it externally exclusively. 5ppm @ 12 volts @ 1.8a. It has a lot of black residue on the silver rods. This came from the high current and the placement of the rods (1.5″ apart from each other). I wont be using this setup anymore.

I have a lot of learning ahead of me. CS generation has many different ways to achieve the same result and it’s quite confusing. Based on my reading, there are dozens of recipes to cook CS. I’m so confused. Isn’t there a scientific procedure backed by multiple studies on the correct and most efficient way to cook CS?

I have come to a conclusion that (by digging very deep) cooking CS requires low current (anything under 500mah). There are CS generators that daisy chain 9volt batteries to end up with 36volts but still having the same 500mah (output of 9volt batteries roughly). Others swear using 9 or 12 volts is adequate (30yrs experience). AtlasNova, from what I deduced, uses high current on their 1 gallon generator (47 volts) yet only uses a fraction of a milliamp current output (500-600 microamps ie 0.5-0.6milliamps). I like these guys because they use low current to make quality CS.

My thoughts? Fudge! Test 2 with 9.22 volts @ 844mah output. I further reduced the output with a 1.5k resistor. So 9.22volts / 1500 ohm = 0.0062 amps ~ 6.2ma. That’s as close to 1 ma I can get so I’m going to use this and test by making a batch to see the results the following night.

This Image displays the alligator clips I soldered to a female 5.5mm x 2.1mm connector so as to avoid splicing into my power brick. Came out nice and clean. Just the way I like it. I had to go get my tools I let a friend borrow. He lost a few screw heads and two allen wrenches out of a set. I shouldn’t have let him borrow my tools because he is irresponsible.

EDIT: 09-16-12

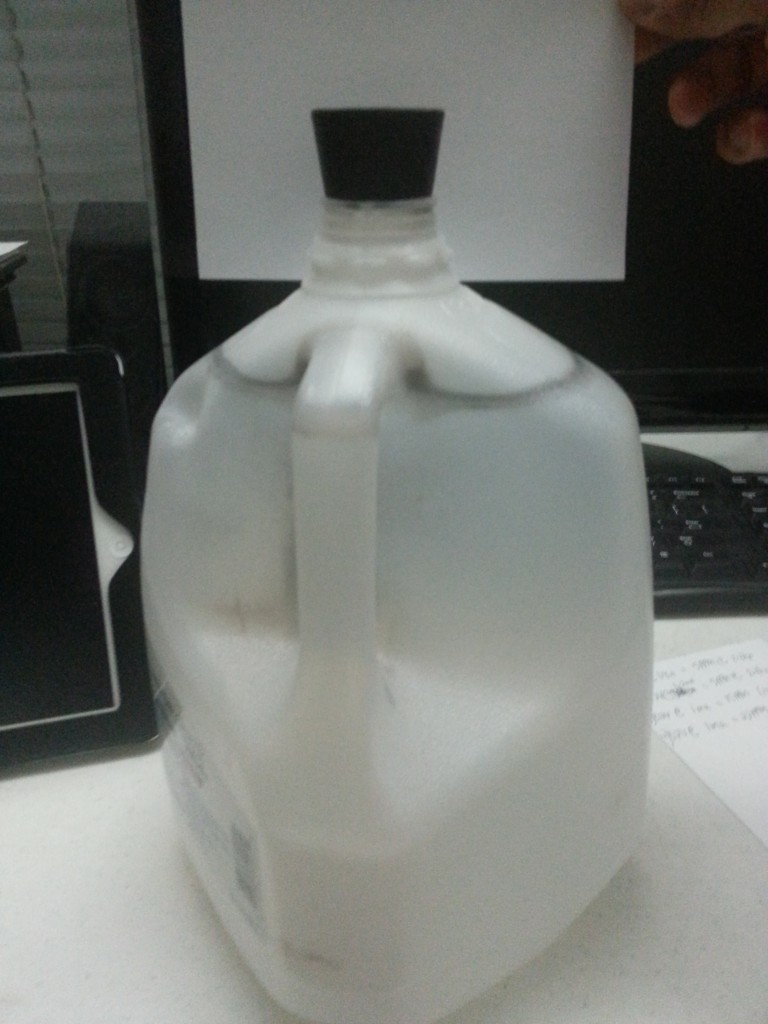

This is after 17 hours. The build up of the sludge is interesting. What’s more interesting is that the water has not turned yellow and I have 4PPM CS. That’s amazing! I’m making quality CS with low current! I’m going to build a magnetic stirring device to circulate the water and hopefully prevent the sludge build up.

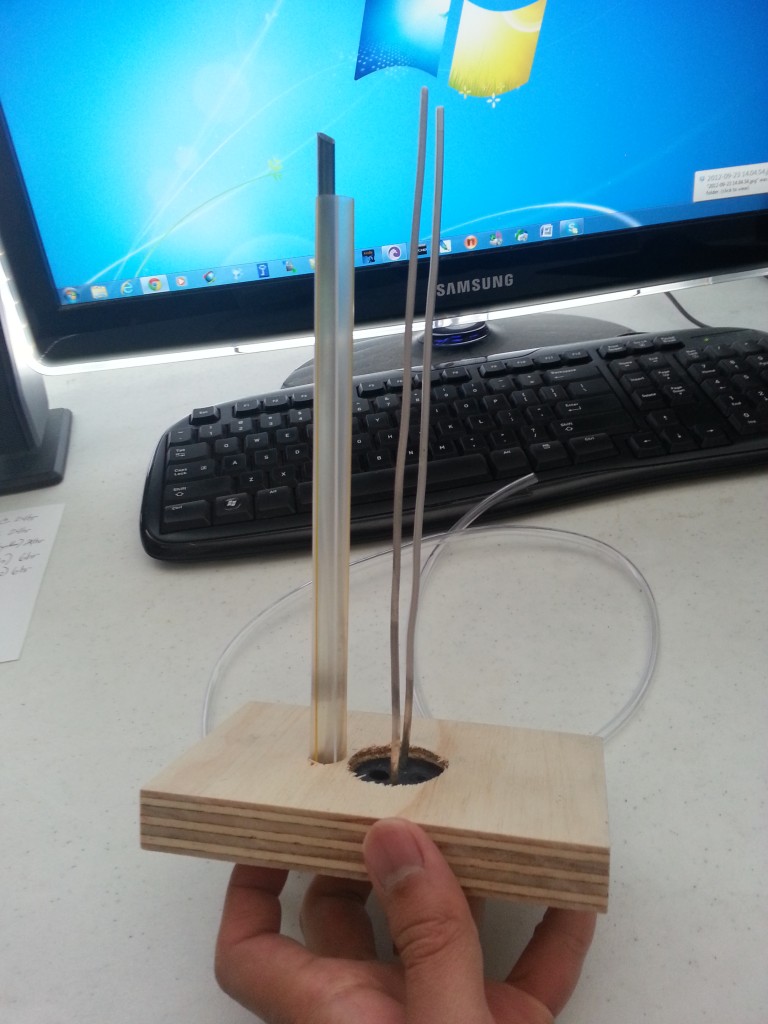

After 24 hr cooking the CS, I have achieved 5PPM. That is roughly 10-12.5PPM because the measuring instrument is calibrated for sodium. There is a difference in color on both batches. The first picture shows the first cook i’v ever made. The second picture shows the second cook. The second cook has higher PPM and is a lot lighter in color. That shows lesser current cooks better quality CS. I’ll cook another later and finish up my contraption.

What’s the difference between LVDC and HVAC Colloidal Silver? (Mountainwellbeing)

LVDC stands for “low voltage direct current” and HVAC stands for “high voltage alternating current.” There are claims that one is better than the other. The truth is they are both good, but the difference is in the polarization. LVDC produced silver particles and ions have a natural (positive and negative) charge just like our bodies, and are absorbed and utilized more effectively than the artificial charge of HVAC produced particles.