Sun 16 Sep 2007

[ratings]

I picked up an AMT 14″ bandsaw and the trunnion was broken. It was cast aluminum (very thin when cast) and so it broke. This is very common of Taiwanese bandsaws. Harbor Freight, Northern Tool, Grizzly- all sale Taiwanese and or Chinese made bandsaws and the parts are interchangeable 99% of the time. They are just marketed under different names and have very little change to differentiate btwn brands etc. Get cast iron trunnions if you can afford it! Lesson learned!

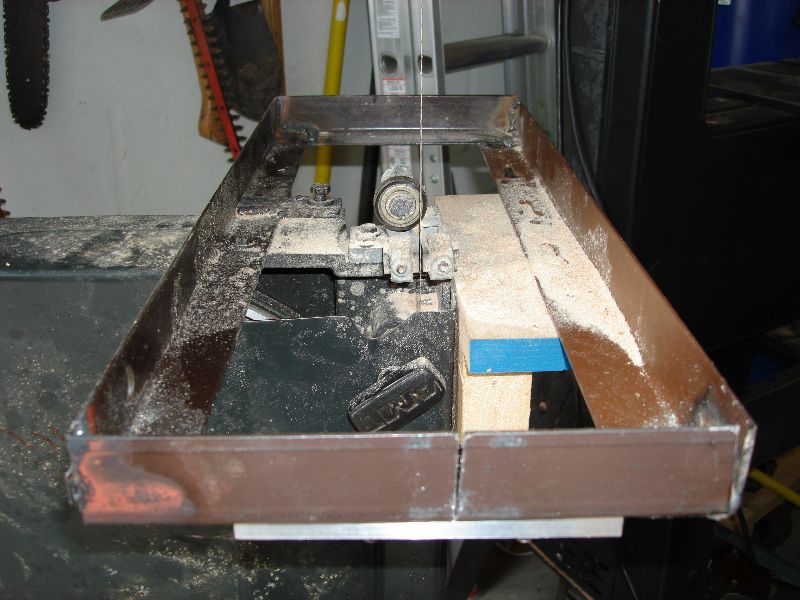

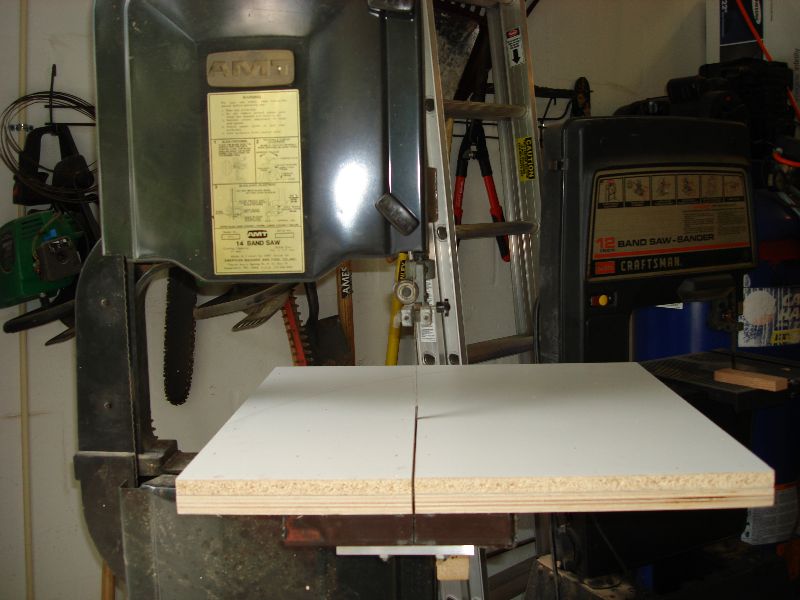

I got it for a sweet deal too! Forty-Five dollars for it and a 32″ wood lathe. I’m fixing to sell the wood lathe though plus the old bandsaw table as well. The bandsaw table is cast iron and it’s quite good castings might I add! If only the trunnions would hold up, I would of had a solid table. Knowing me, I’ll probably upgrade the table anyways just “because”. Well I needed a larger working area and that it must be plumb with the blade. So I made this:

The piece of aluminum you see there, is a bracket to hold the iron frame together. Without it, there wouldn’t be no possible way of putting or taking off the blade. Plus the thick aluminum bracket helps square everything out. I tell ya what, I’m not using bed frame irons anymore unless I’m cutting it with an abrasive disc. The high carbon cold rolled steel is extremely hard! It ruins drill bits and saw blade of any kind in minutes!

My welds look like crap because I forgot to turn on the gas while MIG welding. You can see it with the photo below:

I made the top out of ply nailed to particle board. Reason is because the particle board is smooth and uniform and the ply is for strength. Both combined, will withstand twisting and the surface will always be true. Provided the surface it lies on, is true. I chose melamine to be on top because it allows things to “glide” over it without much friction.

I’ll soon upgrade this with slide railes and I will convert this bandsaw to a metal cutting bandsaw!

Update 09/29/07:

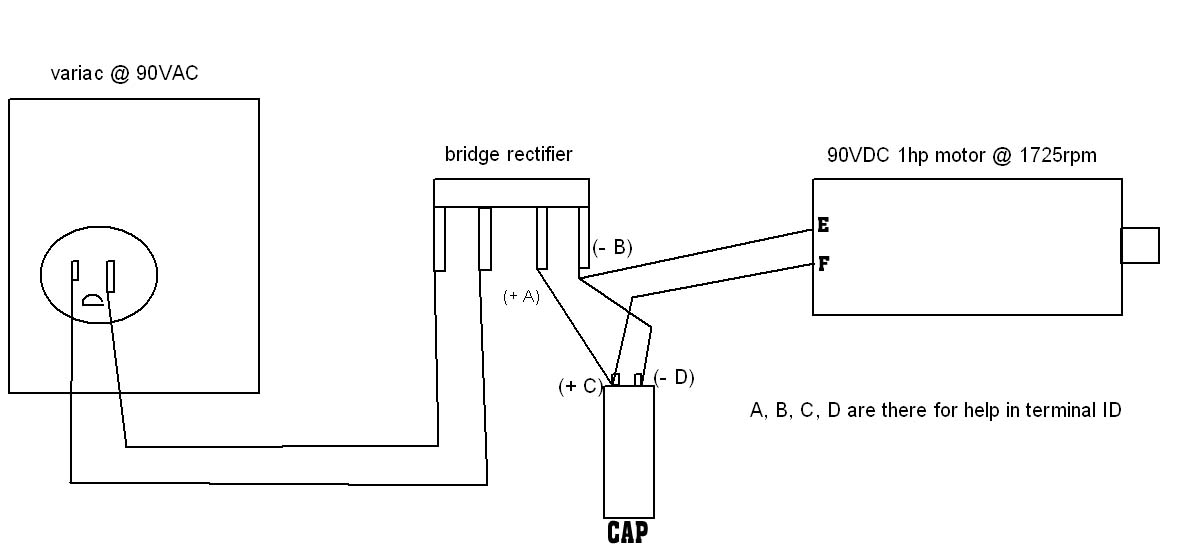

Gear Reducer: Browning Gear

Ratio: 15.1

RPM: 1750

Input HP: 2.61 Output: 1252 Lb. Inch

Shaft: 7/8in/1 1/8in

Reduction Pulleys:

1 sku # 6245K51 : 6″ pulley

2 sku # 6204K515 : 2.70″ pulley

3 sku # 6204K246 : 4.45″ pulley

2.70″ + 6.000″ = 52rpm (metal cutting)

4.45″ + 5.875″ = 88rpm (aluminum cutting)

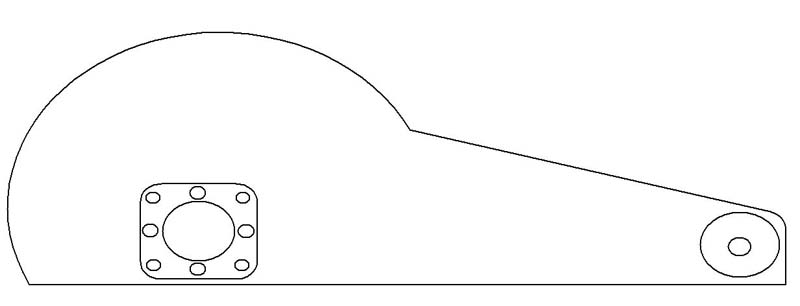

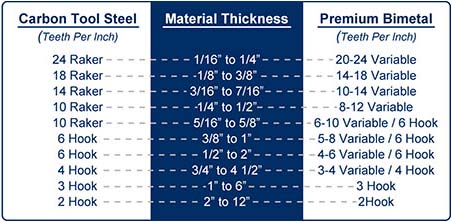

This is the photo of the gear reducer. It has both 2.70″ & 4.45″ pulleys on there. My bandsaw is out of commission because it is waiting to be hooked up to the reducer. Too bad the 6″ pulley can’t fit on there. I’ll have to take my losses and not get the projected rpm I’ve set. I’ll get 53rpm & 88rpm. I’ll be happy with that. I will cut steel and aluminum just fine. I’ll need to get bi-metal blades for it soon. I have supercut carbon steel on there right now (purchased at northertool.com).

More PHOTOS coming!