Wed 17 Oct 2012

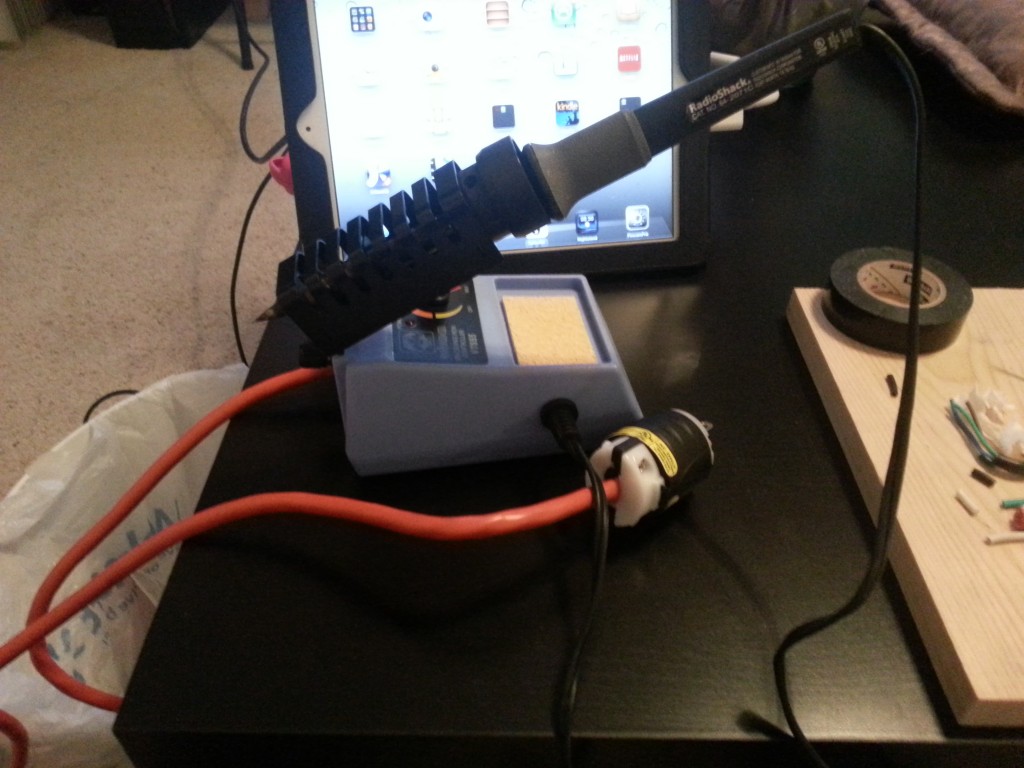

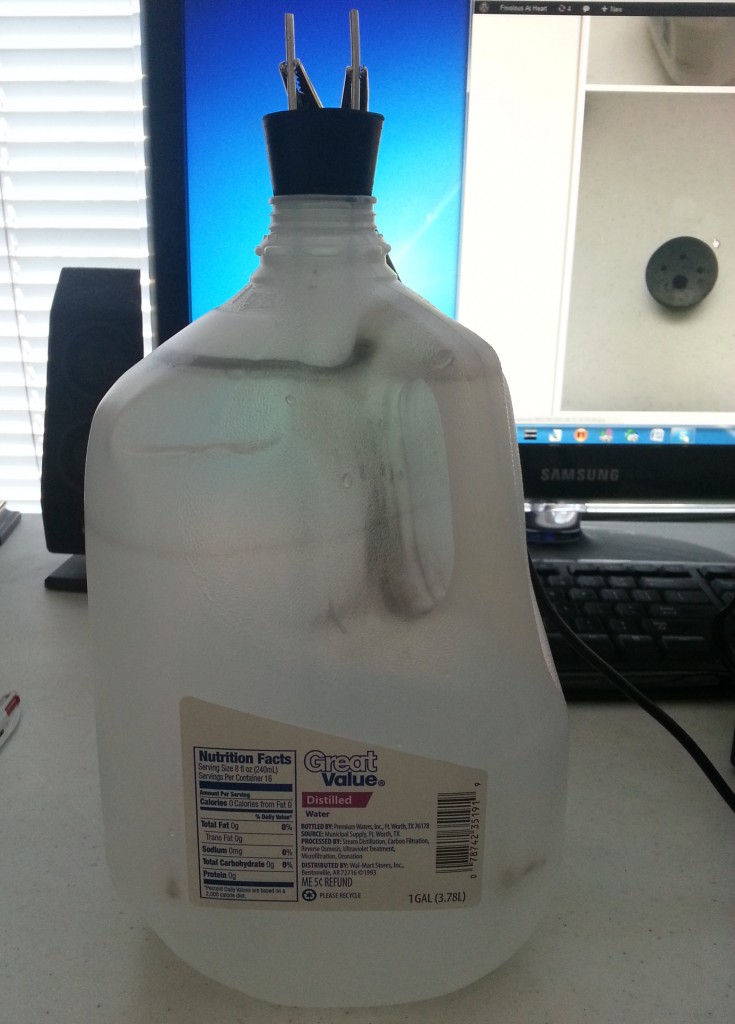

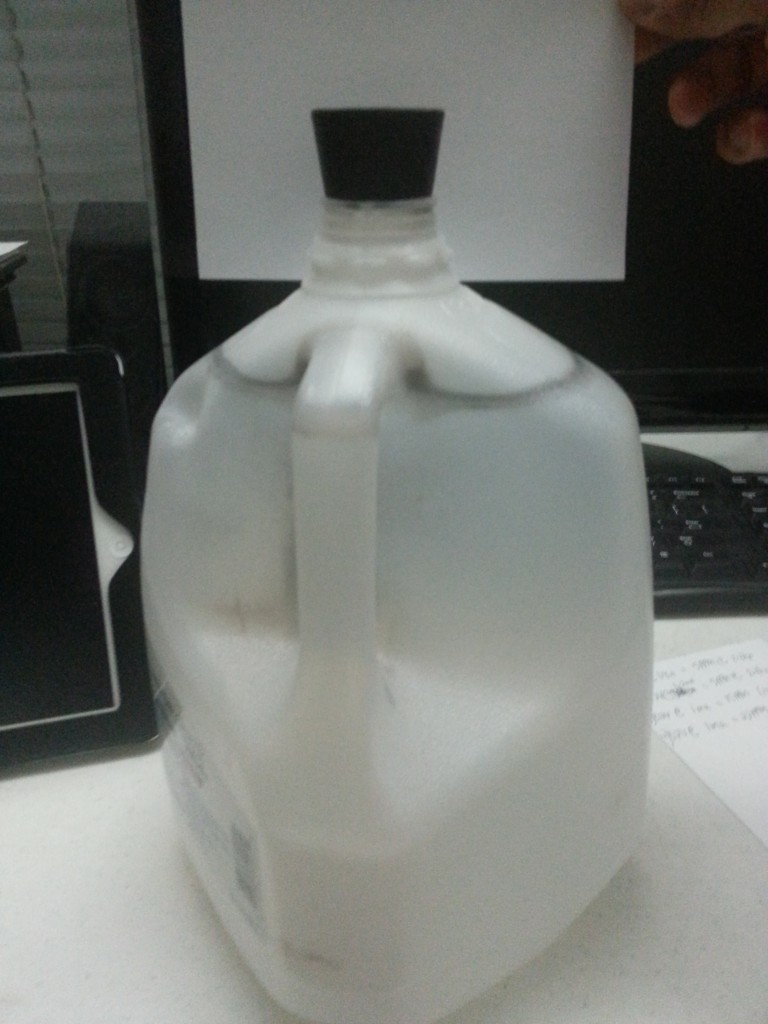

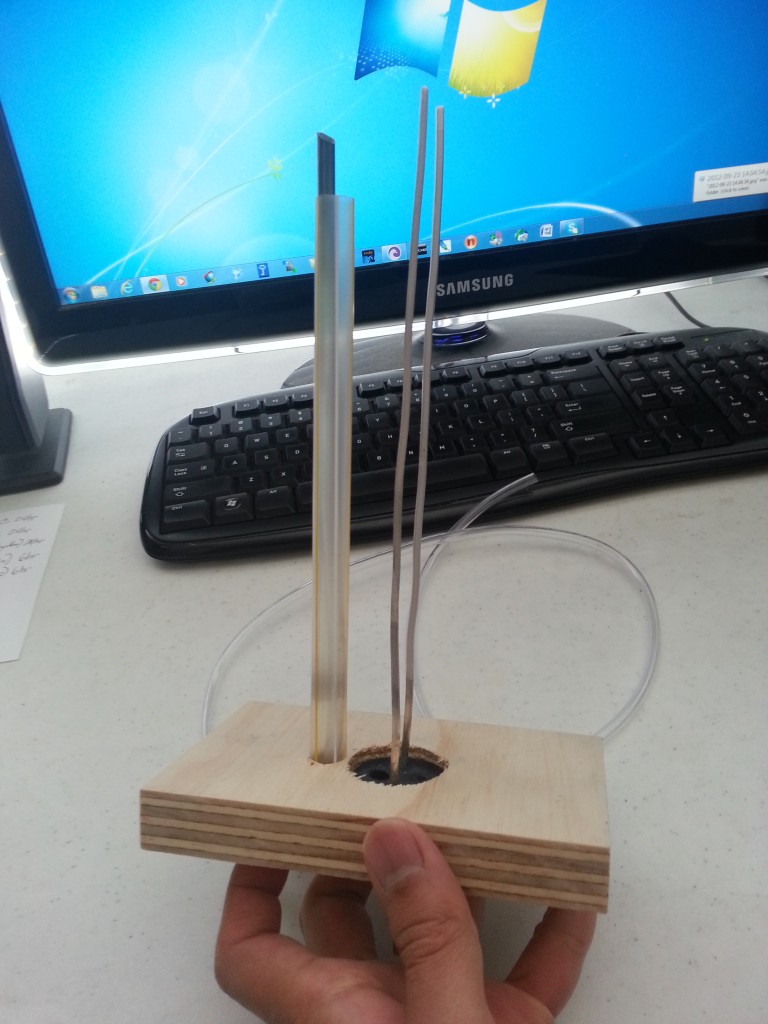

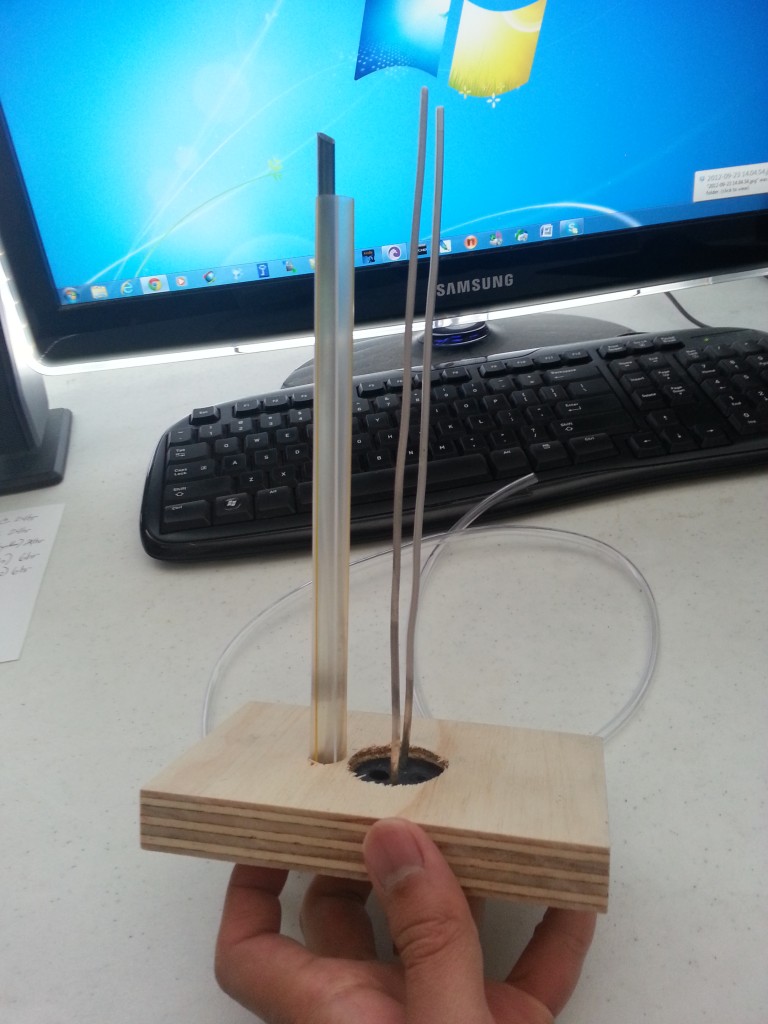

1 oz silver, 36volts, 1000ml DW:

@1ma = 300mins = 5hr cook time

@2ma = 150mins = 2.5hr cook time

@6ma = 50mins cook time

@10ma = 30mins cook time

So I made a cold batch of ionic silver at 10ma for 6hrs. I used the TDS to measure the PPM and i only got 7PPM. I know those readings are wrong now. I actually made more than 20PPM.

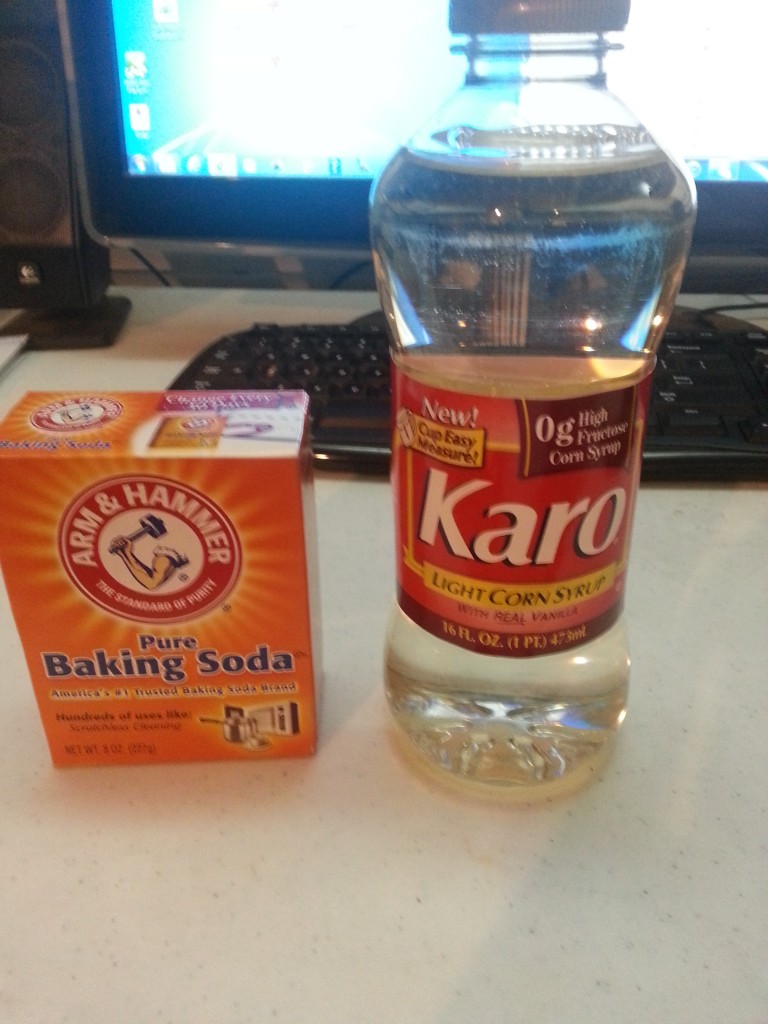

To make Baking Soda Wash:

1) Baking soda in 350deg oven for 1hr = soda wash

2) Took roughly 90ml distilled water + 1 tsp soda wash = soda wash solution

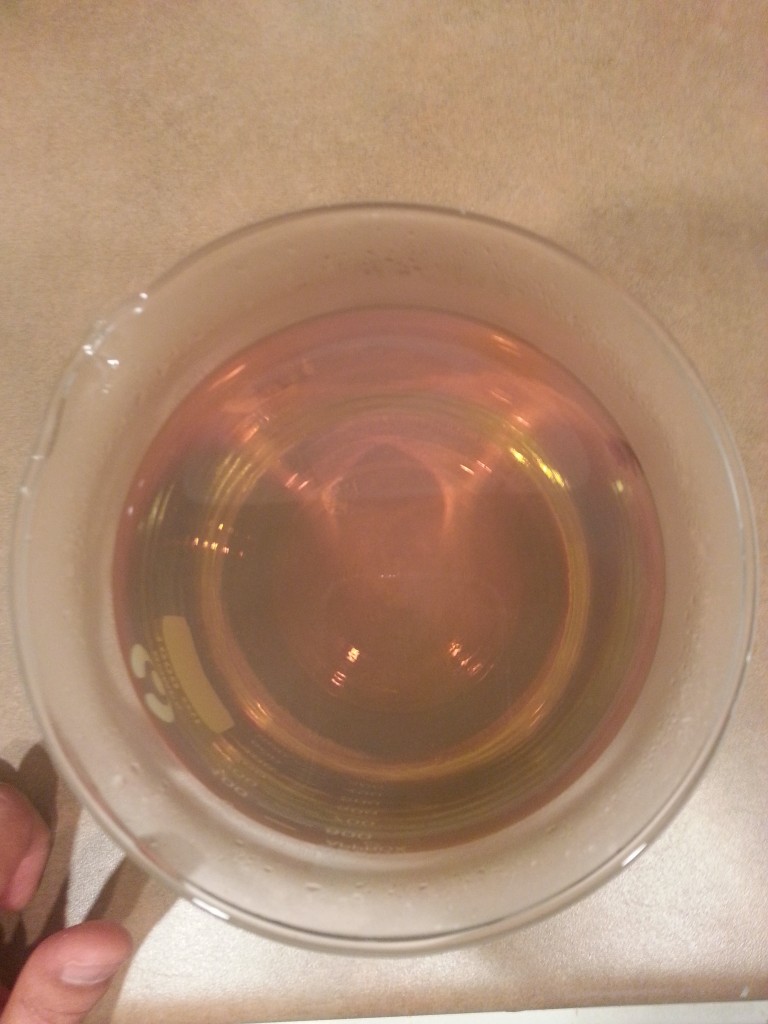

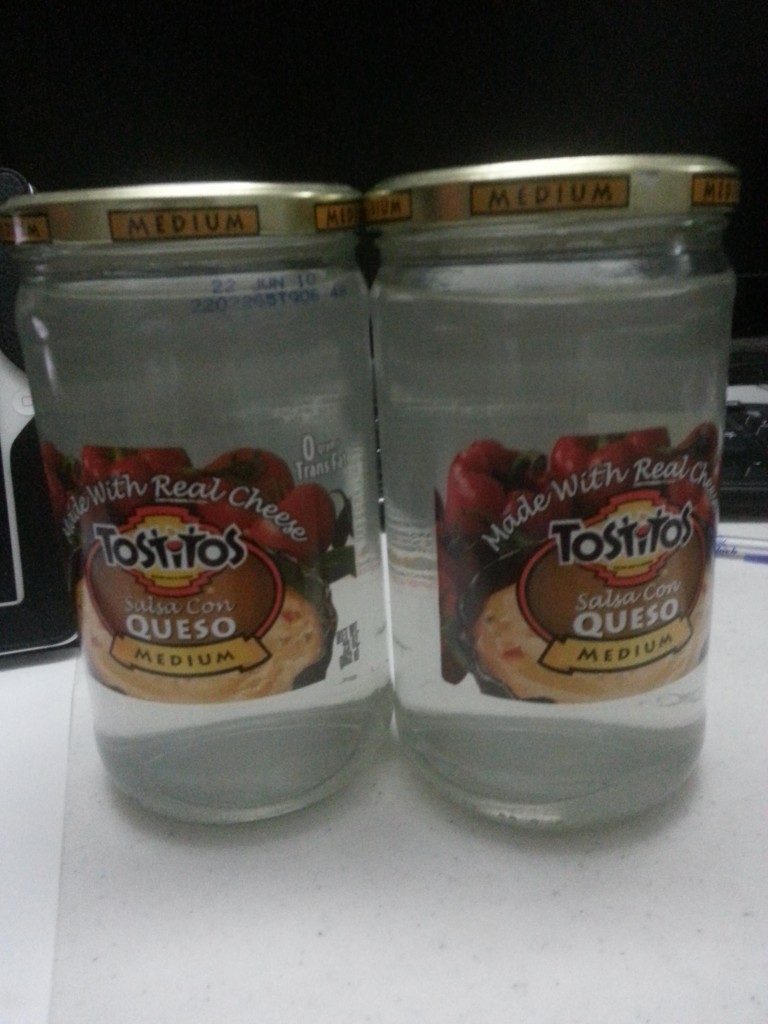

I took 900ml of the ionic silver and poured it into a beaker with 1tsp of soda wash solution + 8-10drops of corn syrup. I put it in the microwave for exactly 7mins and it came out golden yellow. I took a PPM reading just for the hell of it and the reading was 240PPM!!!

10 drops 1/10 tsp 1/60 oz. 1/8 dram 1/2 ml

12.5 drops 1/8 tsp 1/48 oz. 1/6 dram 5/8 ml

25 drops 1/4 tsp 1/24 oz. 1/3 dram 1 1/4 ml

50 drops 1/2 tsp 1/12 oz. 2/3 dram 2 1/2 ml

100 drops 1 tsp 1/6 oz. 1 1/3 dram about 5 ml

150 drops 1 1/2 tsp 1/4 oz. 2 drams 13.5 ml

300 drops 3 tsp 1/2 oz. 4 drams about 15 ml

600 drops 6 tsp 1 oz. 8 drams about 30 ml

24 tsp 8 Tbs 4 oz. 1/2 cup 1/4 pint

48 tsp 16 Tbs 8 oz. 1 cup 1/2 pint

96 tsp 32 Tbs 16 oz. 2 cups 1 pint

http://www.fromnaturewithlove.com/library/eodilutions.asp

—————————————————————————————–

One molecule of maltose will reduce 1 atom of Ag+

It takes 1 mole of maltose to reduce 1 mole of Ag+ ions.

In 1 liter of 20ppm CS there is 20 milligrams of silver.

Converting 20 milligrams to moles: .020/107 = .0001869 moles. (107 is the atomic weight of silver)

So we need .0001869 moles of maltose.

Therefore we need .0001869 liters of 1 Molar maltose solution since 1 Molar maltose contains 1 mole in 1 liter.

0.0001869 liters is .1869 milliliters.

Since there are 20 drops per milliliter, we need .1869 X 20 drops = 3.73 drops (round up to 4 drops) to reduce the 20 milligrams of silver.