Mon 6 Aug 2007

I wanted to make a welder cart for my welder. I know, I could buy one but what’s the fun in that right? So I drew out some preliminary plans based on some of the popular carts I saw around the web. They include:

So I chose the top right corner cart. Made something similar to it. It was fun because all the raw material I had was used bed frames. I knew I would need it one day and so I saved them. I still have a lot more left for other projects. I saved them because they are “L” shaped and holds a true line.

The cart measures 30x12x12. I had it arched up in the front so really it’s 12×15 @ a 15degree angle. You’ll see what I mean when you look at the photos. I took great care in making sure that the bottom was square. I used lots of clamps and was accompanied by a swear-jar.

The platform I used to lay the cart on was not leveled because of the floor having a slight downward grade. So I used two levels to make sure the top and bottom of the cart matched.

Misc shot of me welding it together and finishing up

I reused the wheels off of another cart my friend purchased for me (he got the wrong one).

This is how my welder will fit on there when completed.

Again, I reused the handle that came off the old one. I Cut it in half, the ends are cut at 45degree angles, then welded to the cart.

I’ll paint it black and be done with it!

:::UPDATE::::

I’m finally done with my welding cart. Took me three weeks to do it because I can only work on it on the weekends. Turned out great! For some reason, I like making my own tools lately. Sometimes I save a lot of money and sometimes It costs more to make something than buying it new. That’s besides the point because making it is far better then buying one at any rate.

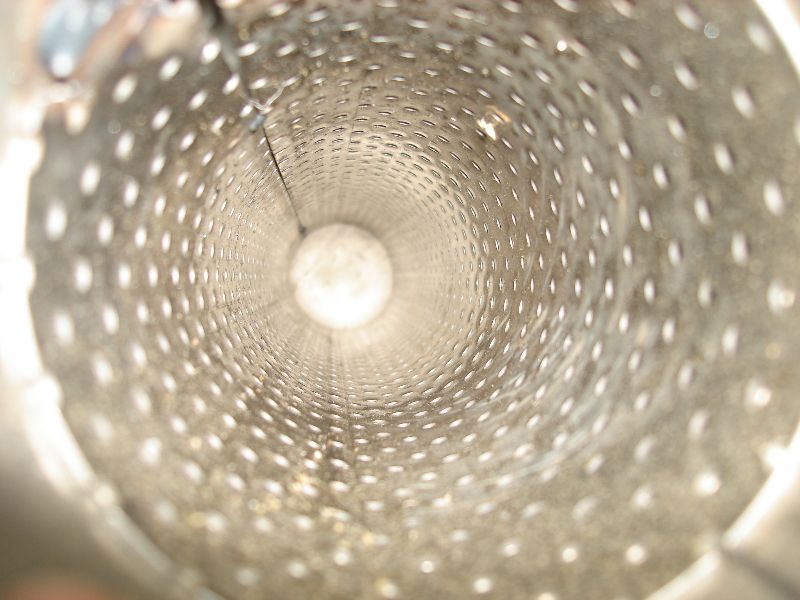

I originally designed my cart for a 20CF argon/co2 tank but I ended up having a 80CF tank instead so the dimensions needed some reworking. I love my welder now; welds are so pretty and clean. Fits nicely on the cart. I never new how heavy everything was. Toting it around the shop on the cart is so much easier on my back then when I had to carry everything. I’m not doing that again! Mobile welder on a cart is something you don’t want to do without.

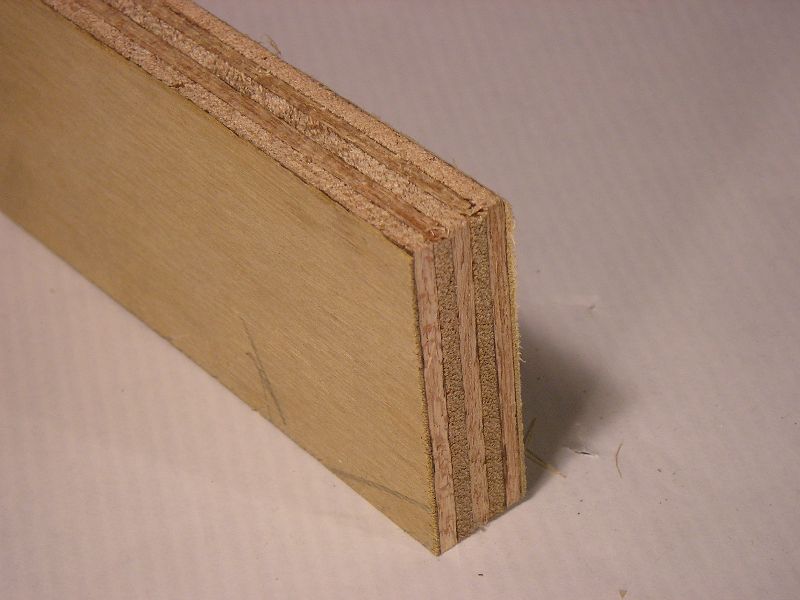

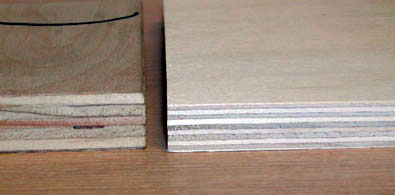

I welded the front caster wheels on Sunday morning. They were galvanized coated and so I had to grind it off prior to welding it on. The angle is just right. I put a box in front of it to put my misc odds in there. It’s not pictured of course but you get the idea. I chose plywood as a platform because it’s much easier to cut than if it were out of mild or aluminum stock.

I was going to paint it but I ended up leaving it the way it is. Works just fine and serves one main service: to tote my welder + argon tank around the shop. It’s made out of used bed frames. I like how the mismatched colors came together; brings out the true luster=)

Build Welder Cart : Homemade Cart : Homemade Welder Cart : Making A Welder Cart